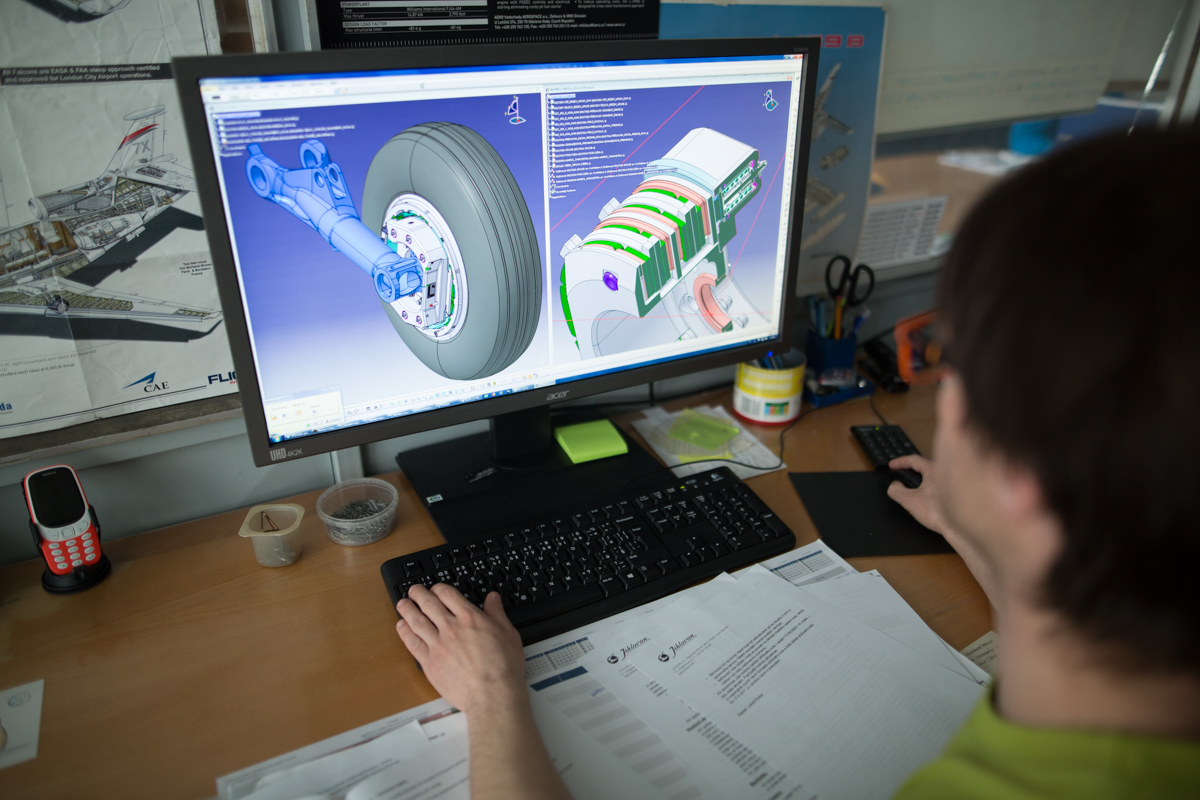

Development work

We have design and development know-how in the following areas:

- Chassis hydraulics

- Hydraulic flight control instruments

- Hydraulic brake instruments

- Hydropneumatic shock absorbers

- Electromechanical tie rod struts

- Brakes

- Wheels

We are the preferred Central European partner for the development, manufacture and service of aircraft hydraulics, electromechanical actuators, wheels and brakes.

We have design and development know-how in the following areas:

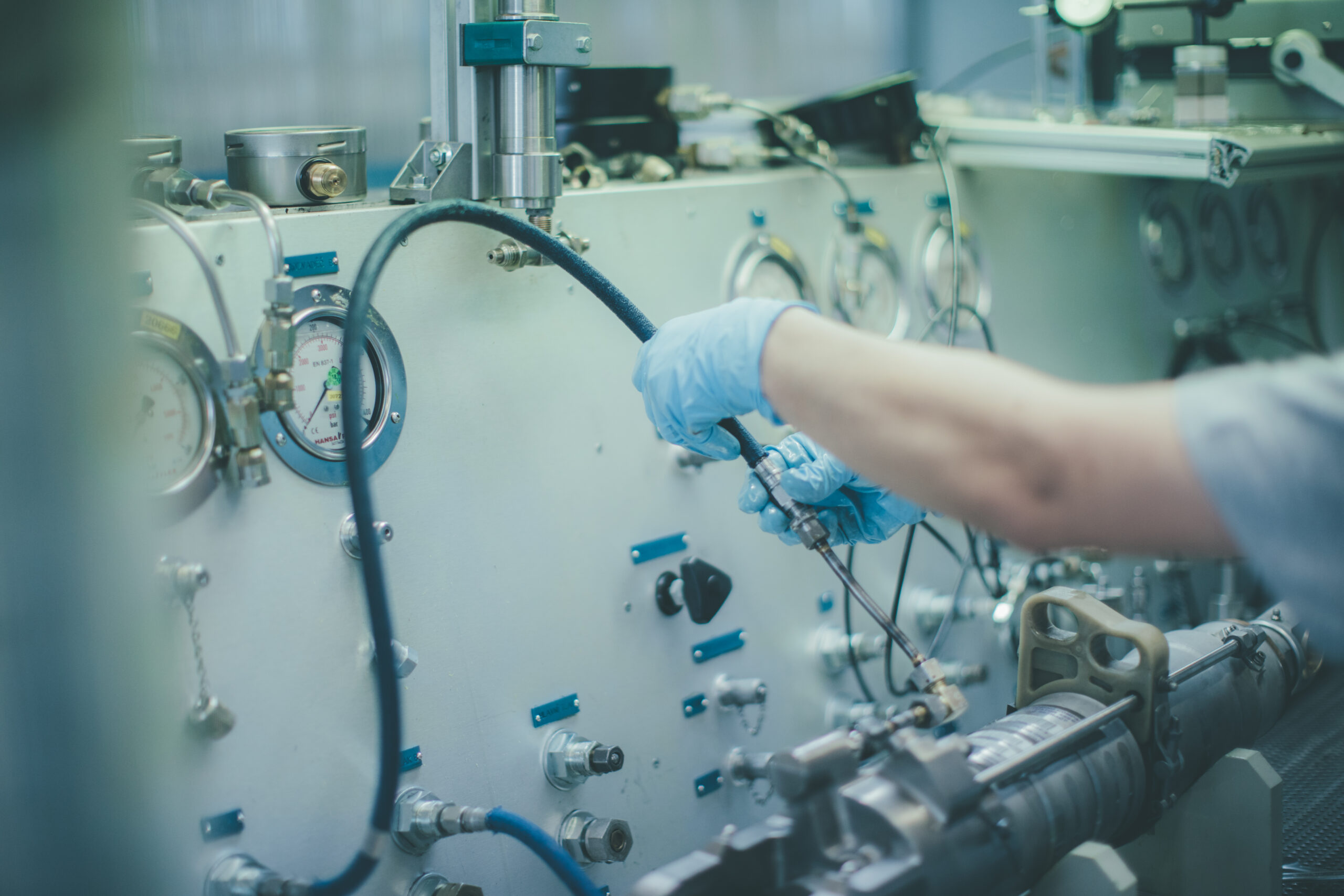

Jihlavan also has the technology and skills to test civil and military aerospace hydraulic (pneumatic) equipment and general purpose hydraulic equipment.

Jihlavan has a comprehensive complex of machine tools from material cutting, through multifunctional CNC machining centers, CNC lathes to CNC grinders and honing machines.

Anodic oxidation of aluminium alloys (Elox). Types: sulphuric anodizing, chromate anodizing and Alodine. All three types under NADCAP certification.

Coating (painting) NADCAP Certified.

Hard chrome coating (chrome plating).

Special processes

Jihlavan has assembly workplaces with controlled cleanliness and temperature stabilization adapted for the assembly of hydraulic and electromechanical devices for on-board systems of General Aviation aircraft as well as large transport aircraft such as Airbus and Boeing.

After installation of the aeronautical instruments, the final tests verify the prescribed functional parameters. Testing is carried out on certified test equipment.

Jihlavan carries out overhauls or service work “according to the condition” of aircraft hydraulic instruments.

Latitude

Longitude

49.389670

15.592290